Corduroy

About Corduroy

Corduroy is a pile fabric with vertical ribs, or "wales" in English terms.

It's a type of weft pile fabric, and is created by weaving two types of weft yarn—pile yarn and ground yarn—and then cutting the pile section.

The primary materials used are short-staple fibers like cotton and rayon, which are ideal for creating the distinct, rich nap and luster of the wales that are difficult to achieve with long fibers.

The width of the wale can vary, and fabrics are often referred to by the number of wales per inch (2.54 cm), such as 18-wale or 6-wale.

In Japan, they are also referred to by terms like "thick cord," "medium cord," or "fine cord."

There are various theories on the origin of the word "corduroy", but the most widely known is from the French phrase "Corde-du-Roi", meaning "the king's cord".

Corde means "cord" or "rib", du means "of", and Roi means "king" (referring to the French monarchy).

As the name suggests, it's believed to have originated during the reign of the Louis monarchy in France.

In Japan, corduroy is also known as "コール天" (kōru-ten), a name derived from the word for velvet (ten-ga-jū) due to its resemblance.

The Corduroy Manufacturing Process

Weaving

The process begins with weaving, where the weft yarns are used to create the pile, or loops. This stage is crucial for controlling the height and density of the corduroy's distinct ribs.

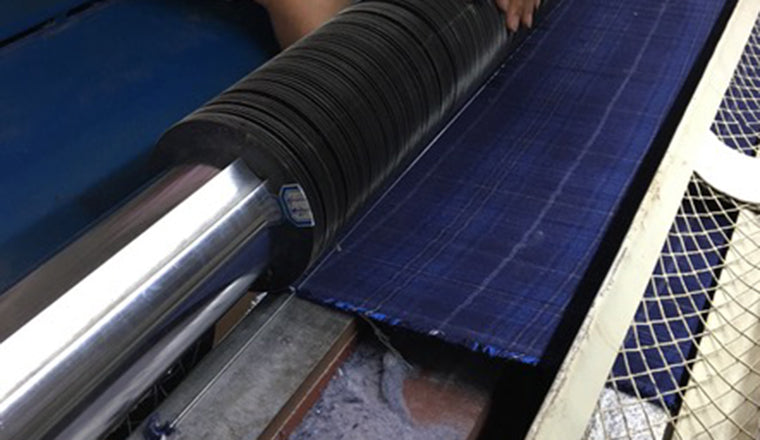

Cutting (The "Cutting" Process)

Cutting is the process of slicing the loops of the pile right down the center. A special guide needle is threaded through the loops on the woven fabric, lifting the pile so a cutter can precisely slice it. This process requires a specialized machine and advanced technical skill, so only a limited number of mills are able to proceed this step.

Rubbing, Singeing, and Finishing

After the cutting process, the pile is loosened and then rubbed with water. The timing of this rubbing is carefully adjusted to ensure the pile stands up neatly. Next, the fabric is dried, and a heated roller is used to singe away any unwanted fibers on the surface of the ribs, tidying up the nap and creating the unique luster. After the various processes, the fabric is dyed and goes to a final finishing treatment to become a completed textile. As you can see, corduroy requires far more manufacturing steps than a standard flat woven fabric. Its fluffy nap and signature luster are the result of specialized machinery and highly advanced techniques.